Heat Exchanger Design Automation Using nTopology & CAD

MECHENG755: Design for Additive Manufacturing | May 2024

This project involved the development of a parametric workflow for designing liquid/liquid counter-flow heat exchangers (HEXs) using Autodesk Inventor and nTopology. The parametric CAD model allowed for rapid adjustments to the dimensions of the HEX given a fixed volume, and the comprehensive nTop workflow automated the generation of gyroid-based cores in the HEX whose cell sizes were dependent on specified thermal parameters. The use of gyroid lattices allows for greater heat transfer than traditional HEX methods and is uniquely suited for additive manufacturing (AM).

-

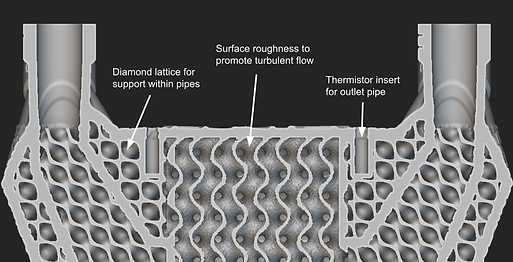

CAD Features: Parametric "pipe within a pipe" design with angled inlet/outlet sections for support-free printing, thermistor inserts, and topology-optimised mounting brackets.

-

Flow Optimization: Ansys Discovery simulations guided the addition of a baffle to improve fluid mixing and heat transfer.

-

nTopology Workflow: Automated gyroid lattice generation with surface textures to enhance turbulence and ribbing for structural integrity. Integrated heat transfer calculations allowed for gyroid cell size optimisation to produce a desired thermal performance.

The design emphasized efficiency and minimal support usage (1272 mm³ of support material compared to 259,449 mm³ of HEX material). The topology optimisation of the mounting bracket, performed using Inspire, allowed for a 30% reduction in the part's weight. Consideration was also given for the material and method of manufacture such as by adding surface textures to improve print quality, reducing large clumps of material and filleting internal edges to reduce stress concentrations, and angling the design as a whole to avoid unnecessary support material.